New update for ICH Q2 (R2) Analytical process validation guidance

As planned for months, the draft ICH Q14 Guideline for AQbD Method Development and the draft ICH Q2 (R2) Guideline for Analytical Process Validation were published at the end of 2023. Both were developed over the past year and come into force in the EMA environment in June 2024. Although at first glance it may be seen as just another regulatory update, this publication is a milestone in the development of analytical processes in a GMP (Good Manufacturing Practices) environment, especially for the ICH Q2 validation guide, as the current version came into force in 1996, 25 years ago.

Naturally, in the last quarter of a century, the transformation of laboratory techniques has been very evident, so the standards were crying out for an update. In fact, in some aspects, such as multivariate techniques like NIR or RAMAN, or those oriented to biological products like PCR or ELISA, the increasing progress of the techniques was unsustainable with the 1996 guidelines.

THE NEW ICH Q2(R2) GUIDELINE

This new edition of the ICH Q2 (R2) stands out from its predecessors for its notable effort to generalize the concepts of validation, opting for them to apply to all methods and thus making it a great ally for all those laboratories that work simultaneously in several processes. Furthermore, unlike the previous edition, it specifically presents detailed recommendations for the evaluation of each parameter in different techniques, making it an effective and very useful manual in practice. Specifically, this current version is structured around four main sections. The first is an introduction in which the complicity with its twin guide, the ICH Q14, is highlighted, presenting a glossary that specifies the origin of each term used and in which of the guides it is recommended to look for more information on each of them.

The second section focuses on considerations when implementing an analytical procedure for quality control in API and drug manufacturing. During these paragraphs, the guide reiterates the need to generalize concepts for application to all methods, and emphasizes widely used multivariate methods such as FT-IR. Specifically, this last part highlights the need to establish a reference method for calibration and the derivation of the model that converts the measured signal into the desired quality attribute.

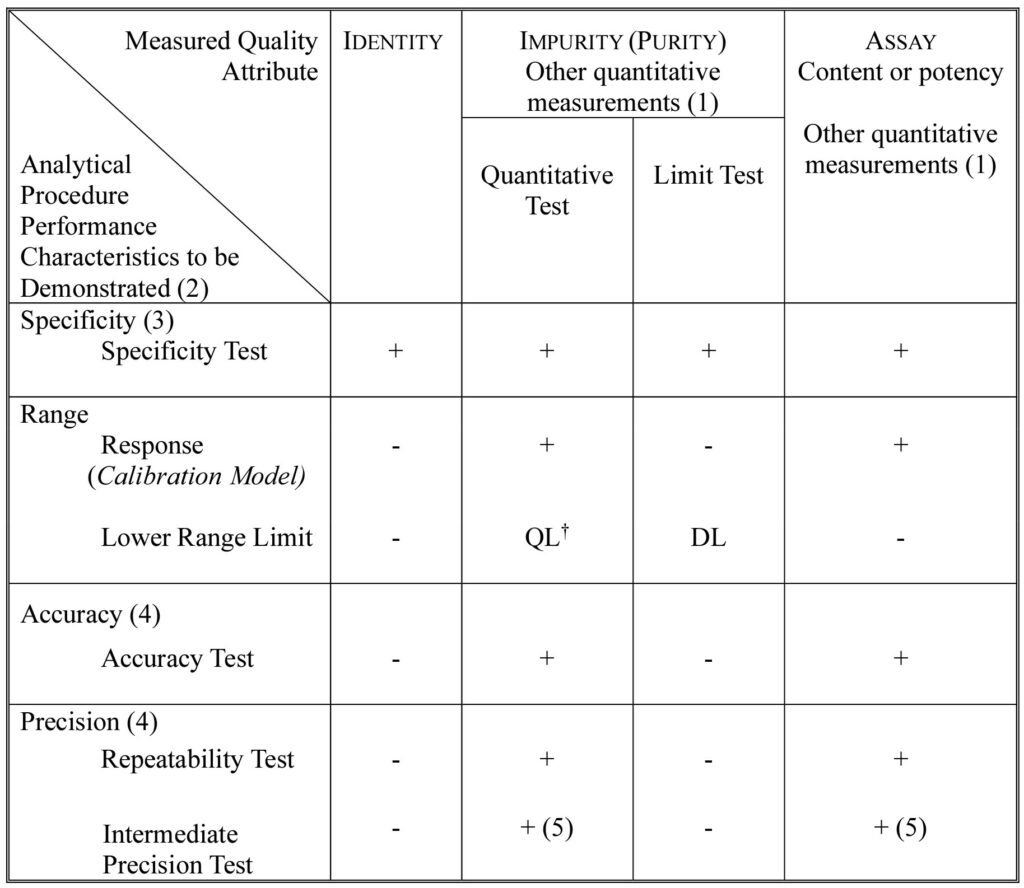

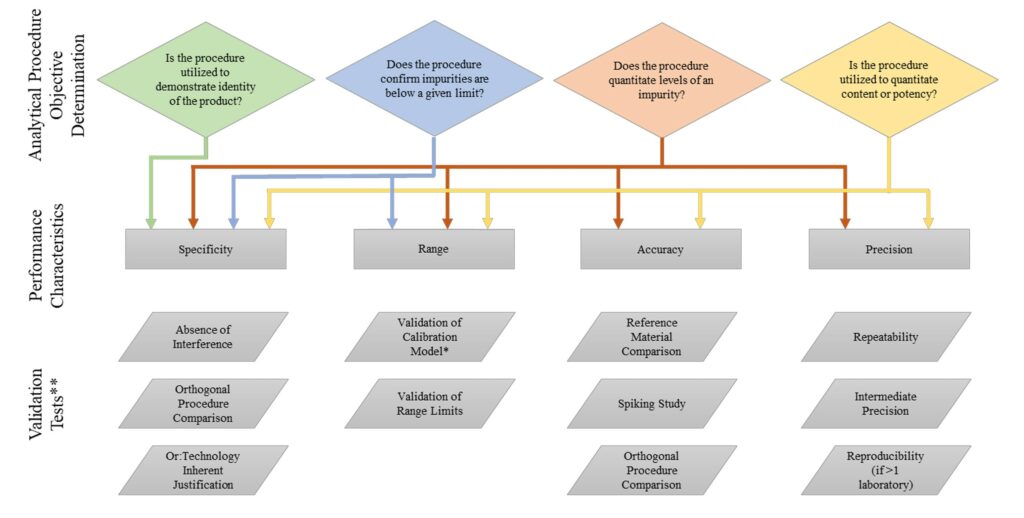

The third section is entirely devoted to the analysis of validation tests, including their methodology and evaluation. Much attention is paid in this part to each of the validation parameters to be studied: specificity and selectivity, range, precision, accuracy, and robustness, recommending that the latter be studied in development and not only as part of the validation itself.

Finally, the glossary mentioned at the beginning and two final annexes are presented, which highlight the detailed treatment of all the information in the guide. Annex 2 contains recommendations on the methodology to be applied for each validation parameter in different techniques. Examples include different separation techniques, such as HPLC, GC or CE; elemental impurity analysis techniques, such as ICP-OES or ICP-MS; HPLC dilution as a product yield test for immediate release, quantitative 1H-NMR for drug testing or the quantitative LC/MS method for impurity analysis, among others.

THE END OF 25 YEARS OF EXISTENCE

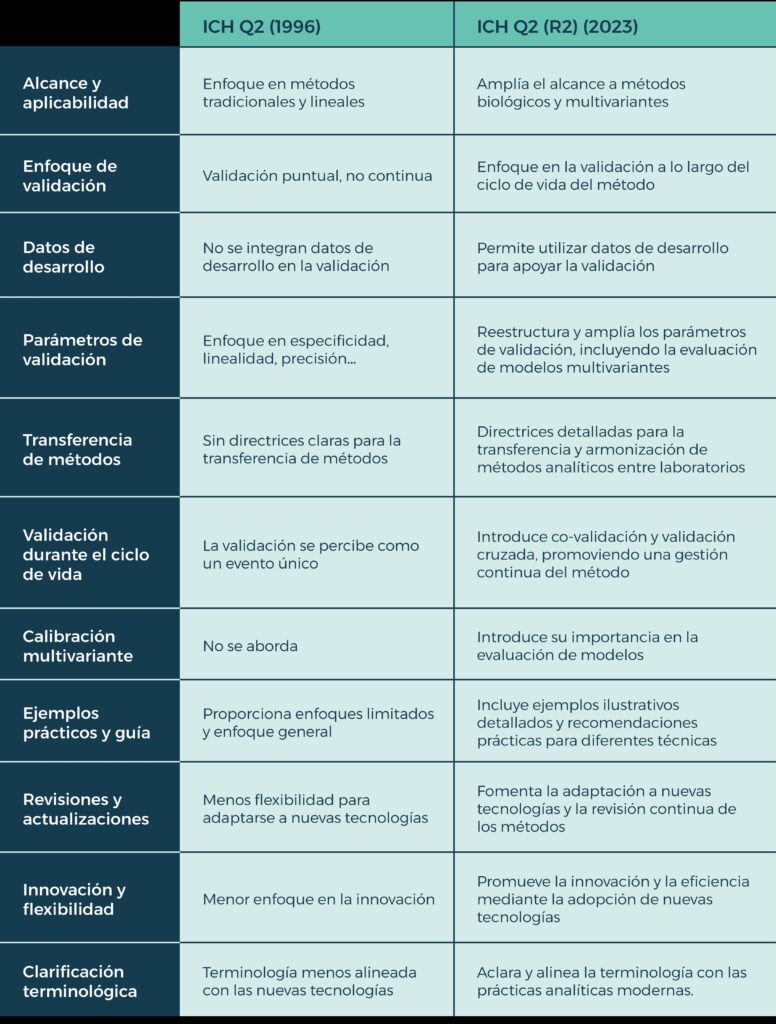

This update to the guide was indeed a long-overdue need for the industry. The sections mentioned above provide a current adaptation to the urgencies of modern industry and facilitate a more robust and flexible framework for daily and routine validation in laboratories. A key example of this is the broadening of the scope of application. The 1996 version focused only on conventional analytical techniques and linear processes, such as HPLC or GC, thus bypassing more advanced techniques that were not as well developed or as commonly used at the time. In contrast, this new version expands its scope to include a much wider range of analytical processes, such as near-infrared spectroscopy (NIR) or high-resolution spectrometry, including the approach to non-linear and biological methods and reflecting the day-to-day reality of modern laboratories.

On the other hand, it should be noted that the current version did not specify in detail the use of development data for the validation of analytical methods, as it focused on obtaining data during the formal validation phase. However, the new guidance does allow data derived from developmental studies to be used as part of validation studies, thereby reducing the need for redundant testing, improving the efficiency of the validation process itself and saving time and resources in parallel. In the same context, the new version also introduces the possibility of reducing validation testing for platform analytical procedures as long as scientifically justified, thus facilitating the transfer of methods between different applications.

In terms of the way the new guidance addresses definitions and terminology, a greater concern for detail can be seen: this version replaces the term “linearity” with “working range”, including “calibration model adequacy” and “lower range limit verification”, thus clarifying the concepts and facilitating a better understanding of validation requirements. In addition, the concept of multivariate calibration is finally introduced, something not addressed in the 1996 version due to the limited use of the method at that time.

But perhaps the two points where the evolution between the two guidelines is most noticeable are in life-cycle validation and method transfer. The 1996 ICH Q2 guideline considered validation as a single event and did not include concepts such as “cross-validation” or “co-validation”, nor did it provide clear guidelines for method transfer between laboratories, which could lead to inconsistencies and challenges in the harmonization of procedures. In contrast, the new ICH Q2(R2) introduces continuous management of the analytical method cycle, promoting harmonization of approaches and consistency in equipment and procedures, which facilitates the transfer of methods such as LC/MS, ensuring their consistency and reliability regardless of laboratory or location.

LC/MS LIFECYCLE IN ICH Q2 (R2)

This new ICH Q2 (R2) guidance is a breath of fresh air at AMS Biopharma, as many of the services we offer rely on modern techniques that have been developed in recent years and whose validation procedures were crying out for updated regulation. One such procedure is the last mentioned technique, LC/MS, offered among our services for the rapid and accurate quantitative determination of organic impurities, a technique whose validation lifecycle is rigorously detailed in Annex 2 of the ICH Q2(R2) Guideline.

The Guideline specifies that the evaluation of parameters such as selectivity and specificity of the method are essential as they constitute one of the major advantages of this technique.

As for the accuracy of the LC /MS method, this must be evaluated by means of spiking studies, which involves determining the acceptable recovery of the analytes, and incorporating internal standards that allow the matrix effect on the MS detector to be managed.

Finally, as part of the development of the LC / MS analytical procedure as outlined in the Guideline, robustness studies are performed. This involves deliberate variations of parameters such as LC flow rate, injection volume, drying/ desolvation temperature of the MS, among others, to evaluate the stability of the test conditions.

It should be noted that it is obviously permissible to initiate validation procedures other than those outlined in the guideline, as long as they are aligned with the general guideline: to ensure the reliability and reproducibility of the analytical method over time.

PERIODIC MODIFICATIONS: A KEY FACTOR

One of the clearest lessons from this new version is the importance of periodic reviews of validation standards. Such updates not only ensure that analytical methods meet the latest standards of accuracy and reliability but also encourage the adoption of new technologies and best practices that can increase the quality and efficiency of analysis. This modernization is essential to maintain the relevance and efficiency of methods in a time of constant change.

The new ICH Q2 (R2) brings multiple benefits to the pharmaceutical and biotech industry, reflecting a modern and adaptable approach to analytical method validation. These benefits include improved quality and consistency of analytical results and allow for greater flexibility and efficiency in managing methods throughout their lifecycle. These include some of those already mentioned throughout the article, such as the extension of the scope of application, the integration of development data and previous knowledge, the improvement in the validation methodology, the classification and terminological consistency, the presence of illustrative examples and practical guidance, the adequate management of the method life cycle, the facilitation of method transfer between laboratories or the promotion of innovation in the development of new methods.

There is no doubt: this new version is a step towards a more modern and flexible approach. By providing a more inclusive and adaptable structure, it facilitates the adoption of new technologies, improves the quality and consistency of analytical results and supports continuous innovation in the pharmaceutical and biotechnology industry.